Premium Blade-Ready Steels – Heat Treated or Untreated

Premium Materials for Serious Bladesmiths

We supply high-quality steel plates and bars suitable for swords and blades,

not limited to CPM 3V. Choose from vacuum heat-treated ready-to-use materials, or untreated bar stock for your own forging and heat treatment process.

We understand the unique needs of bladesmiths – every piece is selected, cut, and prepared to support performance, precision, and craftsmanship.

How can we help you?

Whether you’re a seasoned bladesmith, a growing workshop, or just getting started—we’re here to support every step of your journey. From selecting the right steel to delivering precision-treated materials, we help you turn raw metal into reliable blades. No matter your scale or experience, we treat your craft with care and respect.

Supply heat-treated steel ready for bladesmithing

We offer pre-hardened and tempered plates that are optimized for blade making. Each plate is vacuum heat treated, gas quenched, and triple tempered with distortion control in mind. This saves you time, cost, and the complexity of outsourcing heat treatment, allowing you to focus on shaping and finishing your blade.

Offer untreated bar stock for forging

Prefer forging from raw stock? We supply annealed bars in various sizes that are easy to forge, cut, and heat treat on your terms. Whether you prefer traditional folded forging, differential hardening, or laminated constructions, our untreated steel gives you full creative control.

Help you select the right material for your blade

Every blade has different demands—some require maximum toughness, others demand superior edge retention. We help match your blade design with the right steel based on cutting style, hardness, edge geometry, and finish method. Whether you’re making a katana, chopper, or tactical knife, we’ll recommend what works best.

Provide professional heat treatment data and support

We share detailed heat treatment specifications—including austenitizing temperatures, tempering cycles, and quench methods—based on real test data and manufacturer documentation. Whether you handle your own heat treating or work with a third-party furnace, we help you get the most out of your steel.

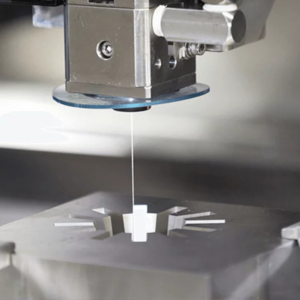

Ensure straightness and EDM-ready finish

Flatness matters—especially for long blades and post-processing like EDM. Our heat-treated plates are jigged with Inconel or composite supports during processing and can be straightened further using press tempering. The result is a stable, EDM-compatible surface with minimal distortion.

Deliver on time, every time

We know timing is everything in bladesmithing—your workbench, heat treat cycle, and finishing schedule all depend on it. That’s why we treat on-time delivery as a core promise, not a bonus. You can count on us to keep your workflow moving.

Real Materials. Real Craftsmanship.

At the heart of everything we do is a deep respect for the materials and the bladesmiths who shape them. Our portfolio represents more than just completed orders—it reflects the precision, reliability, and partnerships that define our work across the global knife and sword-making community.

Our Customers

Our customers are at the heart of our business. We build strong relationships, understanding their needs to deliver exceptional service and results.

"Exceptional Service and Unmatched Expertise!"

Would you like to start a project with us?

Whether you’re crafting a single custom blade or building a full line of swords, we’re here to support your vision with the right materials and reliable service. Tell us what you’re making—we’ll help you choose the steel, prepare it, and get it to you on time. Let’s build something sharp together.