Global Sword Steel Classification & Comparison

With Country of Origin, Hardness, Toughness & Price Range

Whether you’re a traditional bladesmith, a modern knife maker, or simply exploring steel options for your next project, this page offers a comprehensive comparison of sword-grade steels from around the world.

We’ve categorized each steel by type, origin, hardness, toughness, and cost—giving you the insight to choose the right material for your specific needs. From classic high-carbon steels used in hamon-producing katana, to ultra-tough powder steels for modern tactical blades, this guide helps you make informed, confident decisions.

☔Semi-Stainless & Stainless Steels

🔧 Characteristics: Offers rust resistance with performance, great for EDC and wet environments

⚔️ Applications: Tactical folders, outdoor knives, multipurpose blades, culinary knives

| Steel | Origin | Price | Notes |

| D2 | USA | $$ | Very high wear resistance; semi-stainless; more brittle than tough steels |

| S35VN | USA | $$$$ | Premium stainless powder steel; corrosion-resistant with good toughness and edge life |

🧭Steel Selection Summary by Application

| Application | Recommended Steels |

| Traditional hamon swords | T10, W2, 1095, U10A |

| Training & practice blades | 5160, 65Mn, L6 |

| High-impact use / Throwers | S7, 5160, L6 |

| Modern tactical / survival | CPM 3V, Niolox, S35VN |

| Extreme edge holding | CPM M4, T10, D2 |

| Versatile working blades | O1, K720, Niolox |

💎High-Performance Powder & Alloy Steels

🔧 Characteristics: Extreme toughness, wear resistance, or edge retention; difficult to forge but unmatched in performance

⚔️ Applications: Tactical knives, high-end survival blades, laminated core swords

| Steel | Origin | Price | Notes |

| CPM 3V | USA | $$$$ | Exceptional toughness; often used in core laminates; not corrosion-resistant |

| CPM M4 | USA | $$$$ | Ultra-hard steel with excellent edge retention; low corrosion resistance |

| Niolox | Germany | $$ | Semi-stainless with great toughness; versatile for outdoor and kitchen knives |

🛠️Tool Steels (Oil/Air Hardened)

🔧 Characteristics: Good dimensional stability, practical edge retention, moderate wear resistance

⚔️ Applications: Outdoor knives, working blades, axes, multi-purpose tools

| Steel | Origin | Price | Notes |

| O1 | USA | $$ | Easy to machine and polish; oil-hardened; suitable for forging and stock removal |

| S7 | USA | $$ | Designed for impact resistance; excellent for throwing tools and rugged utility use |

| Böhler K720 | Austria | $$ | European O2-type tool steel; good for general-purpose forged blades |

⚙️Spring Steels

🔧 Characteristics: High toughness, flexible under stress, forgiving to heat treat

⚔️ Applications: Choppers, practice swords, machetes, survival and utility blades

| Steel | Origin | Price | Notes |

| 5160 | USA | $ | Excellent toughness & elasticity; widely used for performance swords & axes |

| 65Mn | China | $ | Affordable and easy to forge; ideal for training and throwing blades |

| L6 | USA | $$ | Exceptional spring memory and shock resistance; great for large choppers and laminated core blades |

🏯Traditional High Carbon Steels

🔧 Characteristics: High hardness, excellent edge sharpness, ideal for hamon and traditional forging

⚔️ Applications: Katana, display swords, demonstration blades, historical recreations

| Steel | Origin | Price | Notes |

| 1095 | USA | $ | Simple to heat treat; excellent hamon; relatively brittle under stress |

| T10 | China | $ | Similar to 1095 with higher silicon; clearer hamon and better wear resistance |

| W2 | USA | $$ | Fine-grained steel known for vivid hamon contrast; sensitive to quench speed |

| U10A | Russia | $ | Traditional Russian high carbon tool steel; good for folded & laminated blades |

CPM 3V

CPM 3V is a high toughness, wear-resistant tool steel made by Crucible Industries using the Crucible Particle Metallurgy (CPM) process.

T10 High Carbon Steel

T10 is a classic high-carbon tool steel from China, well-known for its exceptional hardness, excellent edge retention, and traditional hamon-forming capabilities.

1095 High Carbon Steel

1095 is a classic high-carbon steel widely used in knife and sword making. With approximately 0.95% carbon

5160 Spring Steel

5160 is a chromium-alloy spring steel widely used in automotive suspension components, and its toughness and elasticity have made it a top choice in the world of bladesmithing.

65Mn Manganese Spring Steel

65Mn is a Chinese high-carbon, manganese-enhanced spring steel known for its high toughness, elasticity, and wear resistance at a reasonable cost.

S7 Shock-Resistant Steel

S7 is a premium air-hardening tool steel specifically engineered for shock-loading environments.

Why Choose Us?

We’re more than just a steel supplier—we understand bladesmithing from the inside out. Every material we offer is carefully selected, professionally handled, and backed by real technical support.

We understand the real-world needs of sword makers and custom bladesmiths. From steel behavior during forging and quenching to EDM and final finishing, we speak your language—because we’re craftsmen too.

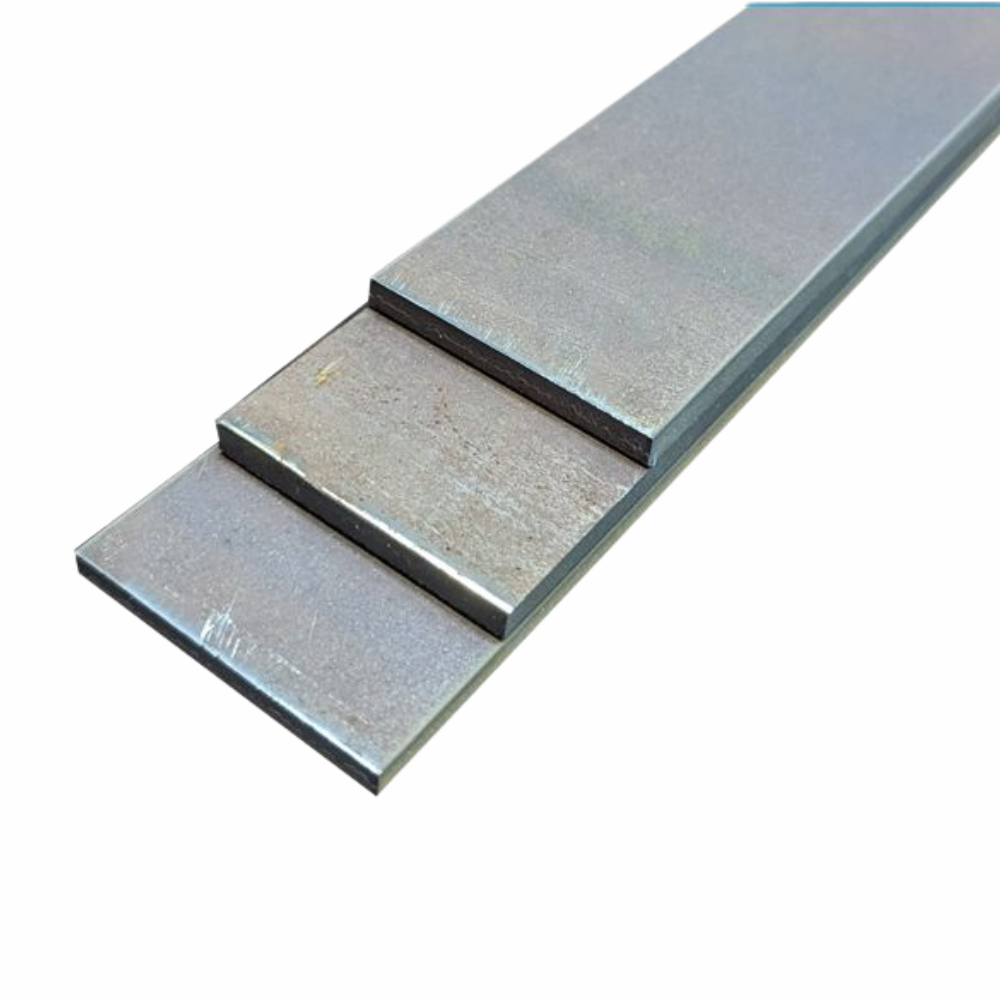

We stock carefully selected steels like CPM 3V, CPM 1V, and more—known for their toughness, edge retention, and dimensional stability. Whether treated or annealed, every batch is chosen for serious work.

Need specific dimensions for your blade profile? We offer custom cutting, stock thickness options, and surface prep to suit forging or grinding—saving you time and material waste.

We focus on long-term value—offering premium materials at fair prices. Whether you’re a one-blade-at-a-time maker or a growing workshop, we’ll work with your budget.

We understand that your build schedule depends on material arriving when promised. We ship on time, provide tracking, and follow up—so you can plan with confidence.

Have questions about heat treatment, material choice, or blade geometry? We’re here to help—not just before the sale, but anytime you need practical advice.

Some Numbers

Explore a glimpse of our data

Years of Experience

Satisfied Clients

Steel Plates Supplied

Expert Heat Treats

Would you like to start a project with us?

Whether you’re crafting a single custom blade or building a full line of swords, we’re here to support your vision with the right materials and reliable service. Tell us what you’re making—we’ll help you choose the steel, prepare it, and get it to you on time. Let’s build something sharp together.